Introduction

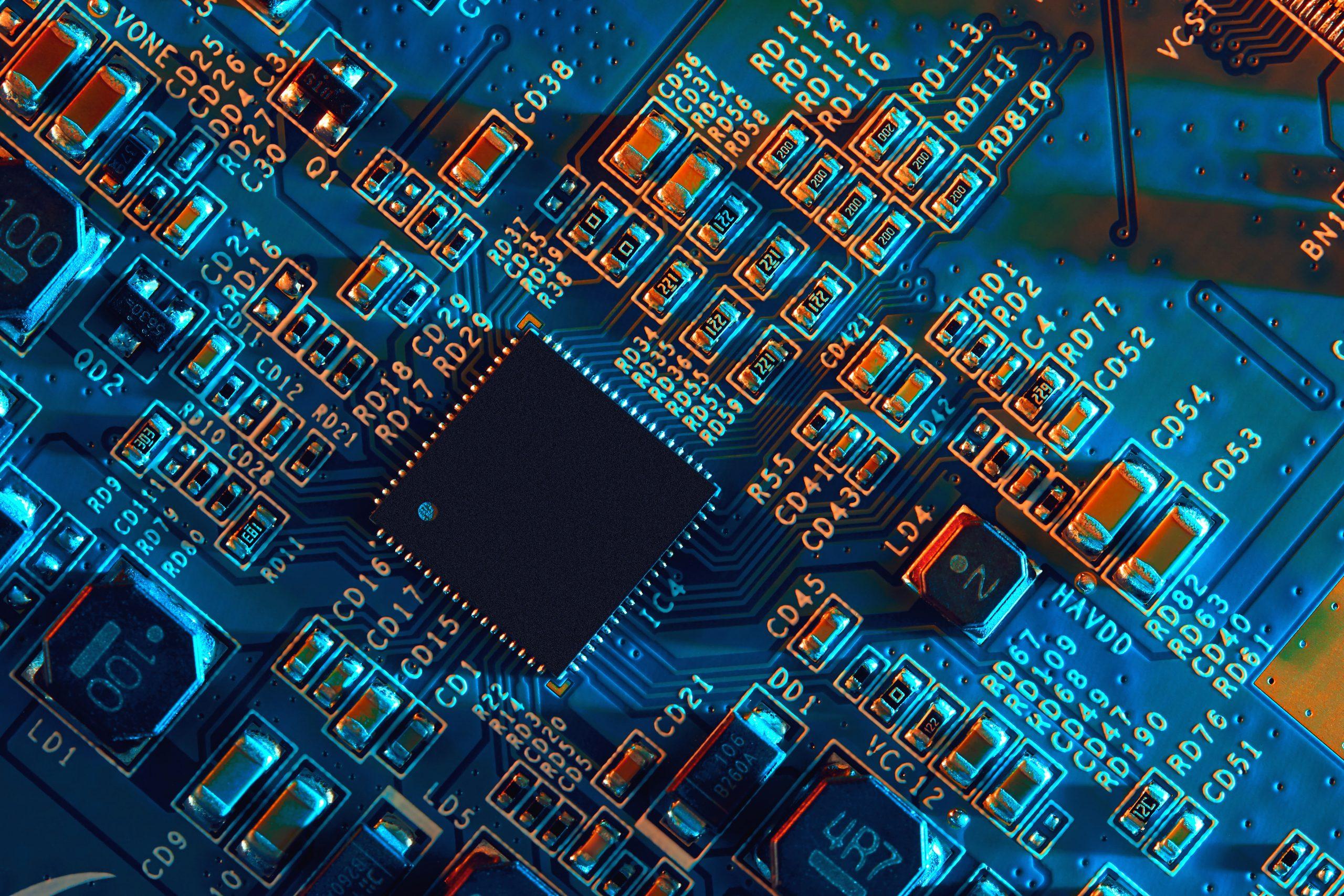

Printed circuit boards (PCBs) are the unsung heroes that keep our electrical devices running in today's ever-changing technological landscape. PCBs have come a long way since their inception, and as we look to the future, exciting developments are on the horizon. In this article, we will delve into the emerging trends in PCB manufacturing that promise to revolutionize the electronics industry.

Miniaturization and Miniaturization

There is a growing need for smaller, more compact PCBs as electronic gadgets become ubiquitous daily. Miniaturization is a trend that has been gaining momentum for years, and it's showing no signs of slowing down. Manufacturers are constantly striving to make PCBs smaller without compromising performance. This trend has led to the development of high-density interconnect (HDI) technology, which allows for more components to be placed on a single PCB, reducing the overall size of electronic devices.

Miniaturization makes devices more portable and opens up new possibilities in industries such as healthcare, where miniature PCBs can be implanted in the body for medical monitoring and treatment.

Flexible and Wearable Electronics

The rise of flexible and wearable electronics is another exciting trend in PCB manufacturing. Printed circuit boards (PCBs) that are flexible, or flexible PCBs, can be molded to fit unusual or irregularly shaped components. This flexibility allows for the creation of innovative wearable devices like bright clothing, fitness trackers, and even flexible displays.

Integrating flexible PCBs into everyday attire and accessories is poised to transform how we interact with technology. These thin, lightweight, and durable PCBs, make them ideal for applications requiring continuous movement and flexibility.

5G Connectivity

The advent of 5G technology is set to usher in a new era of Connectivity and communication. Printed circuit boards (PCBs) form the backbone of 5G networks, allowing for increased data transfer speeds and decreased latency. To accommodate the high-frequency communications and complicated designs of 5G networks, printed circuit boards (PCBs) used in these networks must be manufactured using state-of-the-art procedures.

The need for PCBs supporting 5G networks is expected to skyrocket as 5G networks are rolled out worldwide. This development will have far-reaching consequences, touching the telecommunications industry, autonomous cars, smart cities, and the IoT.

Sustainability and Green Manufacturing

In recent years, there has been a shift toward greener practices in the electronics industry. Printed circuit board (PCB) production has grown more eco-friendly in recent years.

One notable development is the use of recycled materials in PCB manufacturing. Reclaimed copper and other components can create eco-friendly PCBs without compromising quality. Additionally, the shift toward lead-free soldering and environmentally friendly coatings reduces the environmental impact of PCB production.

Advanced Materials

The choice of materials in PCB manufacturing plays a crucial role in performance and durability. Emerging materials trends include using advanced composites, such as ceramic PCBs. Because of its excellent heat resistance and high thermal conductivity, ceramic printed circuit boards (PCBs) find widespread use in the aerospace, automotive, and power electronics industries.

Furthermore, there is a growing interest in organic substrates and laminates, which offer improved signal integrity and reduced signal loss. These materials are becoming increasingly popular in high-frequency applications like 5G and aerospace electronics.

Automation and Industry 4.0

Automation and adopting Industry 4.0 principles are transforming the PCB manufacturing process. Advanced robotics, artificial intelligence, and data analytics are integrated into production lines to enhance efficiency, reduce errors, and streamline quality control.

With the help of automation, manufacturers can achieve higher precision in PCB assembly and testing, ultimately leading to more reliable and cost-effective electronic products.

Conclusion

The future of electronics is undoubtedly bright, with exciting trends in PCB manufacturing driving innovation across industries. Miniaturization, flexible electronics, 5G connectivity, sustainability, advanced materials, and automation are shaping the landscape of PCB production and electronic device development.

PCB makers will be crucial in addressing customer demand for smaller, more powerful, environmentally friendly electrical gadgets. The evolution of PCB technology is enhancing our gadgets' performance and opening up new possibilities for industries and applications we can't even imagine yet. So, buckle up for a thrilling ride into the future of electronics, where PCBs are at the forefront of innovation.

Also read about:

Managing Concussions The Role of a Concussion Management Clinic

Revitalizing Womens Health A Deep Dive into Pelvic Floor Physiotherapy

The Best Furniture Sales In Dubai